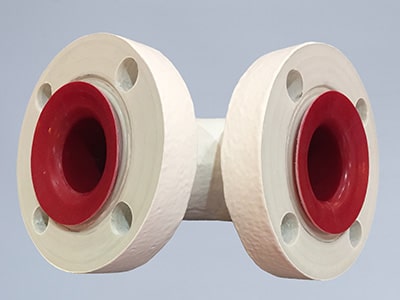

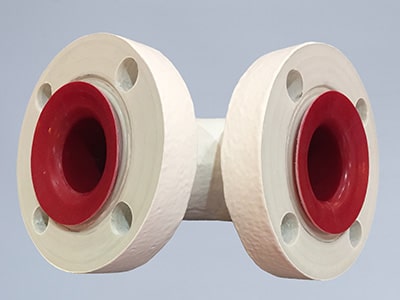

MAXAR™ Red, one of several lines of dual laminate piping available from RPS Composites, is now manufactured using Kynar Flex® PVDF as the corrosion barrier layer.

Kynar Flex® PVDF copolymer has many unique properties that extend the options for engineers, designers, and maintenance personnel. Not only is it designed for increased chemical resistance in the pH range of <1 up to 13.5, Kynar Flex® has higher tensile elongation than traditional PVDF materials leading to ductility at ambient and colder temperatures, and allowing for easier assembly and flaring. The material has a UL® RTI rating of 130℃, and is a strong barrier against permeation of acids, chlorine, and bromine at lower temperatures.

Suggested applications for MAXAR™ Red piping include hot strong acids such as benzoic, chromic, citric, fatty olefin, fluorosilicic, hydrobromic, hydrochloric, hydrofluoric, methane sulfonic, nitric, phosphoric, salicylic, and sulfuric. Other applications include brine, brominated solutions, chlorinated solutions, aliphatic and aromatic hydrocarbons, wastewater mixtures of these chemicals, and more. Kynar® and Kynar Flex® PVDF materials are also highly abrasion resistant thermoplastics, making them useful for applications with slurries or other abrasive media.

It’s in these acidic environments where the performance of a non-metallic is a real advantage. RPS MAXAR™ Red offers longer life, less maintenance, no venting or collection systems, and more assembly options than lined steel. Furthermore, by replacing unnecessary flanges with shop or field joints, the fully bonded, seamless, MAXAR™ Red is less expensive and more dependable than lined steel. Combined with RPS’s MAXAR™ Blue (FEP- Lined FRP) and MAXAR™ White (PFA-Lined FRP), MAXAR™ Red, Kynar Flex® PVDF-Lined FRP, compliments our complete suite of corrosion resistant dual laminate piping systems.

RPS MAXAR piping systems are part of the RPS High Performance Pre-Engineered (HPPE) suite of corrosion resistant piping solutions. Available seamless from 1.5” to 12” diameters, and shop welded up to 24” diameter, with a wide array of fittings and flange options, MAXAR™ Red can be part of a complete new install or a complete or partial replacement of a lined steel piping system. With dual laminate piping experience dating back to 1982 and nine manufacturing and service locations in the USA, RPS utilizes qualified bonders to either pre-assemble MAXAR™ Red piping spools in the shop, join the components in the field, or most commonly, a combination of both.

RPS Composites’ MAXAR™ Red 90º flanged FRP elbow made with Arkema Kynar Flex® PVDF liner.

Download the technical bulletin, Seamless MAXAR™ Red PVDF/FRP Dual Laminate, for complete details.

Kynar Flex® is a trademark of Arkema Inc.

MAXAR™ is a trademark of RPS Composites, Inc.