RPS mining and mineral processing customers with locations in Canada, the US, Mexico, and South America benefit from the superior performance of our fiberglass reinforced plastic (FRP) piping, tanks, and vessels. We’re proud to be awarded significant grassroot projects by both asset owners and global EPC firms procuring the non-metallic piping supply. In many cases we are awarded the installation scope as well.

FRP piping for solvent extraction

In solvent extraction processes, FRP piping is commonly used to transport solvents, feed solutions, and extracted substances between various process units, such as mixers, settlers, and evaporators. Its ability to resist chemical corrosion and provide a reliable and durable solution makes it a popular choice for these critical applications. Proper design, installation, and maintenance are essential to ensure the safe and efficient operation of FRP piping systems in solvent extraction and other mineral processing methods.

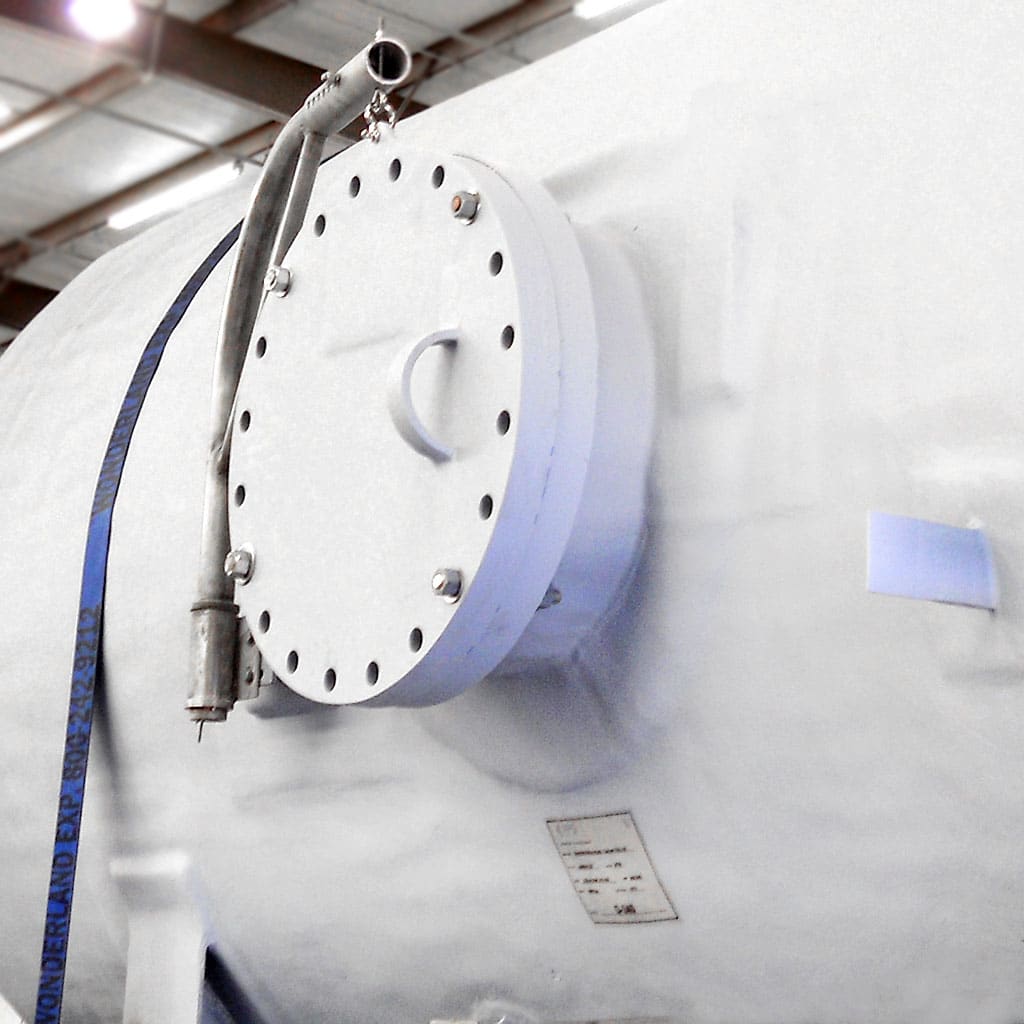

RPS has manufactured FRP duct, wastewater piping, acid storage tanks, process vessels, and process piping for solvent extraction, electrowinning, and other types of mineral processing facilities. Our customers also benefit from the expertise and craftsmanship of our Field Service teams. Most commonly, we provide maintenance and shutdown service, pipe and tank inspections (including in-service inspections), and emergency repair.

Governments and industry continue to explore strategies to diversify mineral sources and develop domestic mining capabilities to reduce reliance on a few key suppliers. The earlier we are involved in your project, the earlier we can start making a positive impact on your design and your bottom line.