Atlantic Bridge Company (ABCO) begins making FRP piping and other FRP products in Mahone Bay, Nova Scotia.

Ft² of manufacturing area

Ft of pipe manufactured

Spools assembled

RPS Composites manufactures and services high-performance corrosion resistant tanks, vessels, and piping systems for industrial customers who need to transport, store or process corrosive fluids. Our customers choose to work with us again and again because they know we will provide them with the safest, highest value-per-dollar products and services in the market – almost always in aggressive and difficult to manage environments where failure is not an option.

Welcome to RPS Composites – your trusted partner in providing cutting-edge corrosion-resistant solutions since 1956. With a legacy rooted in excellence, innovation, and quality, we are the leading manufacturer and service provider of high-performance corrosion-resistant tanks and pipe systems. Our expertise lies in engineering solutions that not only transport, store, and process corrosive fluids but also stand the test of time, ensuring optimal performance and unparalleled safety.

Spanning over six decades, we’ve pioneered the application and advancement of fiberglass reinforced plastic (FRP) and dual laminate equipment. Our journey is marked by relentless innovation, as we continuously enhance our offerings to meet the evolving needs of the diverse industries we serve, including chemical processing, mineral processing, power generation, water treatment, and pulp & paper.

At RPS Composites, we are on a mission to empower industries globally to realize the full benefits of corrosion-resistant composite materials. We are steadfast in our commitment to delivering the safest, highest value-per-dollar products and services in the market. Every solution we engineer is a blend of cutting-edge technology, world-class quality, and cost-efficiency, ensuring that our clients achieve operational excellence and sustainable growth.

Our strength lies in our diverse team of dedicated professionals, each bringing a wealth of experience, skill, and innovation to the table. Comprising engineers, field technicians, product designers, skilled manufacturing specialists, and project managers, we are united by a shared commitment to problem-solving and customer success. At RPS Composites, we believe that when it counts, experience matters – and we are proud to be the experienced hand that our clients reach for, time and again.

How can our team help?

We are driven by a set of core values that define our approach and underpin every solution we deliver. Integrity, innovation, and excellence are at the heart of our operations. We are unwavering in our commitment to safety, quality, and value, ensuring that every project we undertake not only meets but exceeds the expectations of our clients.

Discover the RPS Composites difference – where innovation meets experience, and quality is our number one priority. For more information or to discuss your specific project, contact us today.

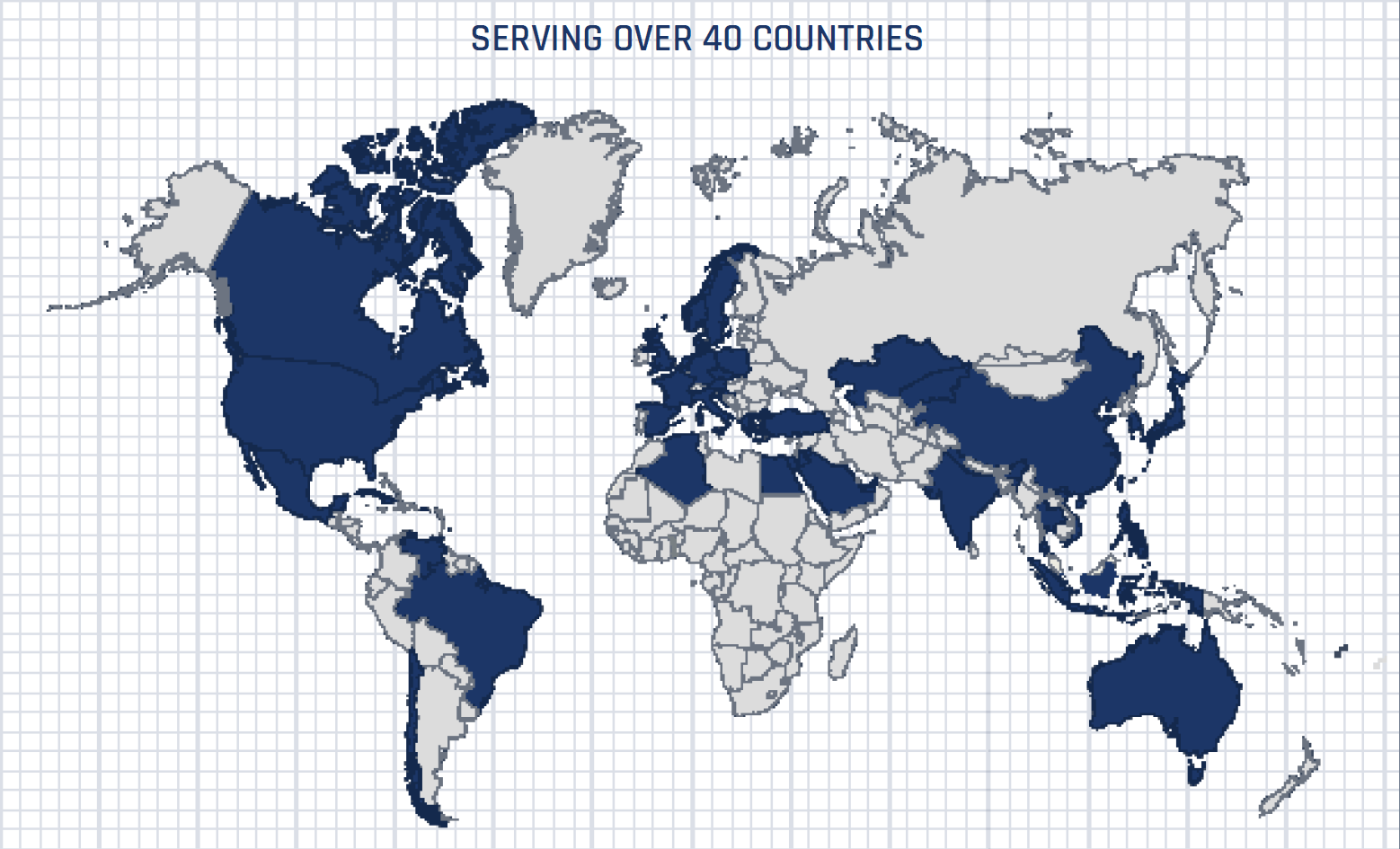

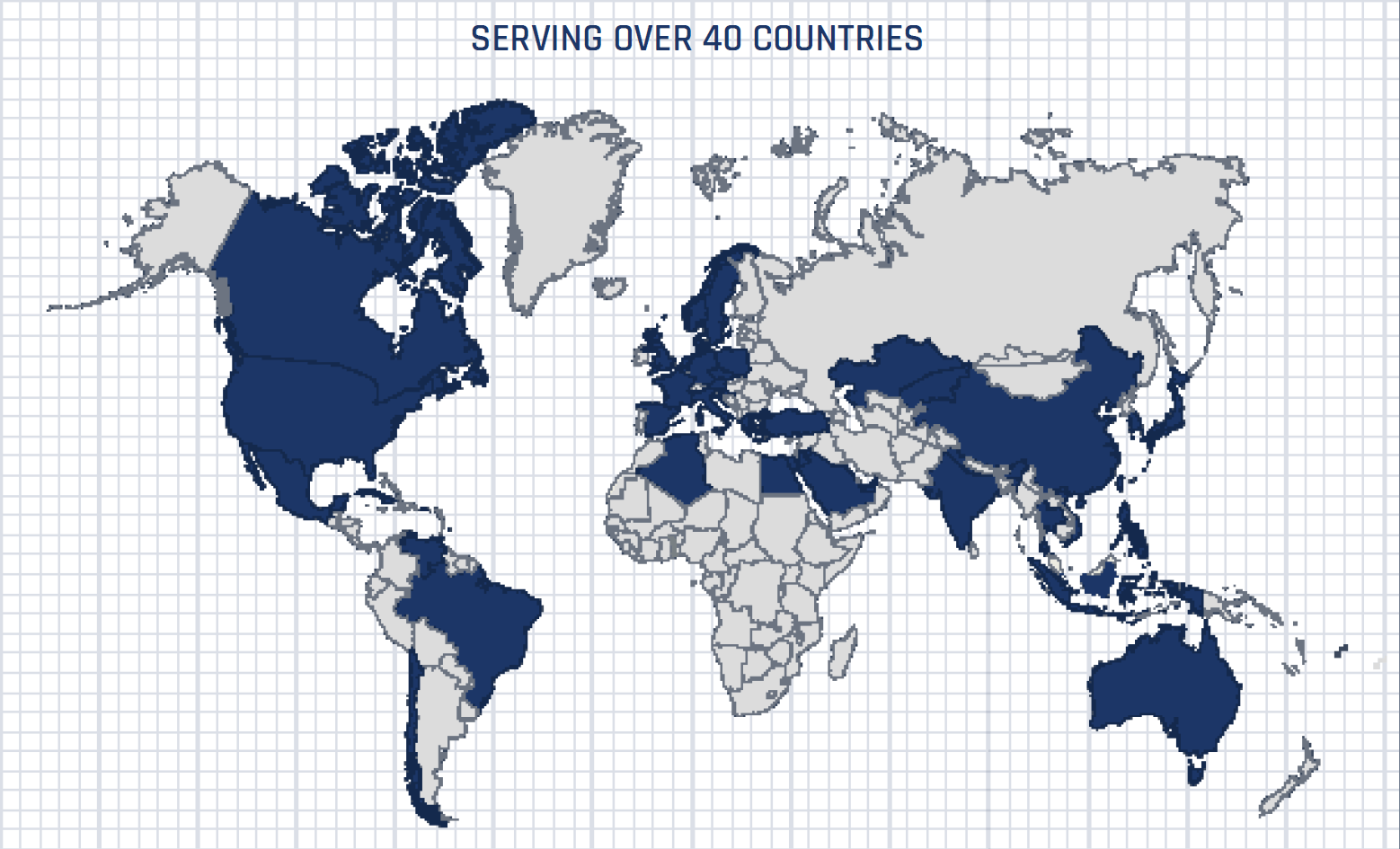

Hundreds of installations in more than 45 countries around the world are the best demonstration of our experience in providing composite solutions for corrosive fluid handling, storage, and infrastructure challenges.

Through a series of acquisitions and organic growth, we operate FRP and dual laminate manufacturing, inspection, distribution, and service centers near Mobile, Alabama; Birmingham, Alabama; Baton Rouge, Louisiana; Houston, Texas; Washington, DC; Columbus, Ohio; Pittsburgh, Pennsylvania; Salt Lake City, Utah; Vancouver, Washington; Toronto, Ontario; and Halifax, Nova Scotia; with total manufacturing area of approximately 300,000 ft2, and close to 100 field service technicians.

Ft² of manufacturing area

Ft of pipe manufactured

Spools assembled

Reach out for more information about the wide variety of products and operational expertise RPS offers our customers.