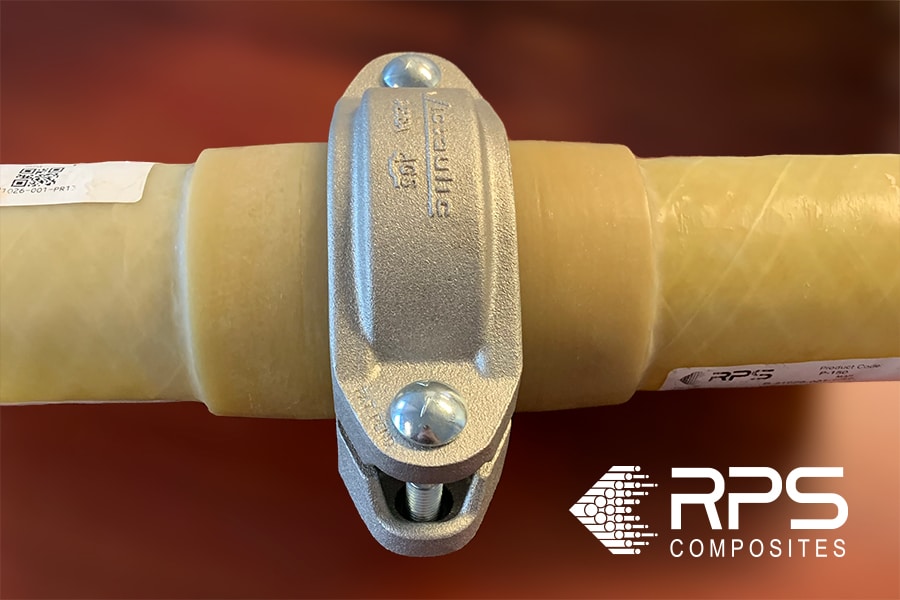

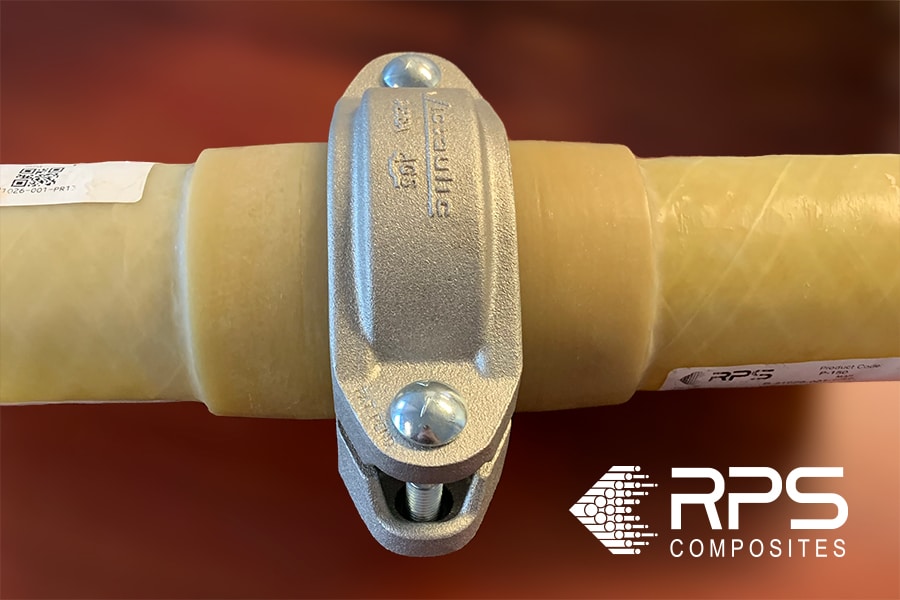

RPS Composites is pleased to announce the availability of the newly engineered RPS Grooved Adapter to be used in conjunction with RPS FRP piping systems and a Victaulic® Style 296-A coupling to create a robust, reliable FRP piping joint.

The FRP adapters were tested in accordance with the Proof of Design test requirements of ASME NM.2-2020, which include a series of hydrostatic strength, static pressure, and cyclic pressure tests. The qualification test program was successfully completed; therefore, the adapters comply with the requirements of ASME NM.2-2020. The adapters were also tested in a pipe bending test to demonstrate a factor of safety of no less than 6 in bending with a coincident pressure of 150 psi.

Designed for both the corrosion resistant P-150 piping system as well as the corrosion and abrasion resistant A-150 piping system, customers can be confident the joint will maintain the rating of the piping systems, i.e., 150 psi at 180°F (10 Bar at 82°C).

The RPS Grooved Adapter joining system will be a welcome addition to the many options already available. Up until now, customers could choose to join their piping systems by the traditional butt and wrap joint, the tapered adhesive joint, the bell & spigot O-ring joint, and by a variety of flange options. The choice is always based on a number of factors including chemical media, pressure, pipe diameter, liner thickness, and skill level of installation labor.

It’s expected that ease of use will be the most attractive characteristic of this joint as it can be coupled or uncoupled in a matter of minutes with no special tools or training. The RPS Grooved Adapter is designed for mildly corrosive environments including water, seawater, wastewater, and some FGD services, up to 180°F and 150 psi, and is available in 2” – 12” diameters.

For more information, or to place an order, please Contact Us.