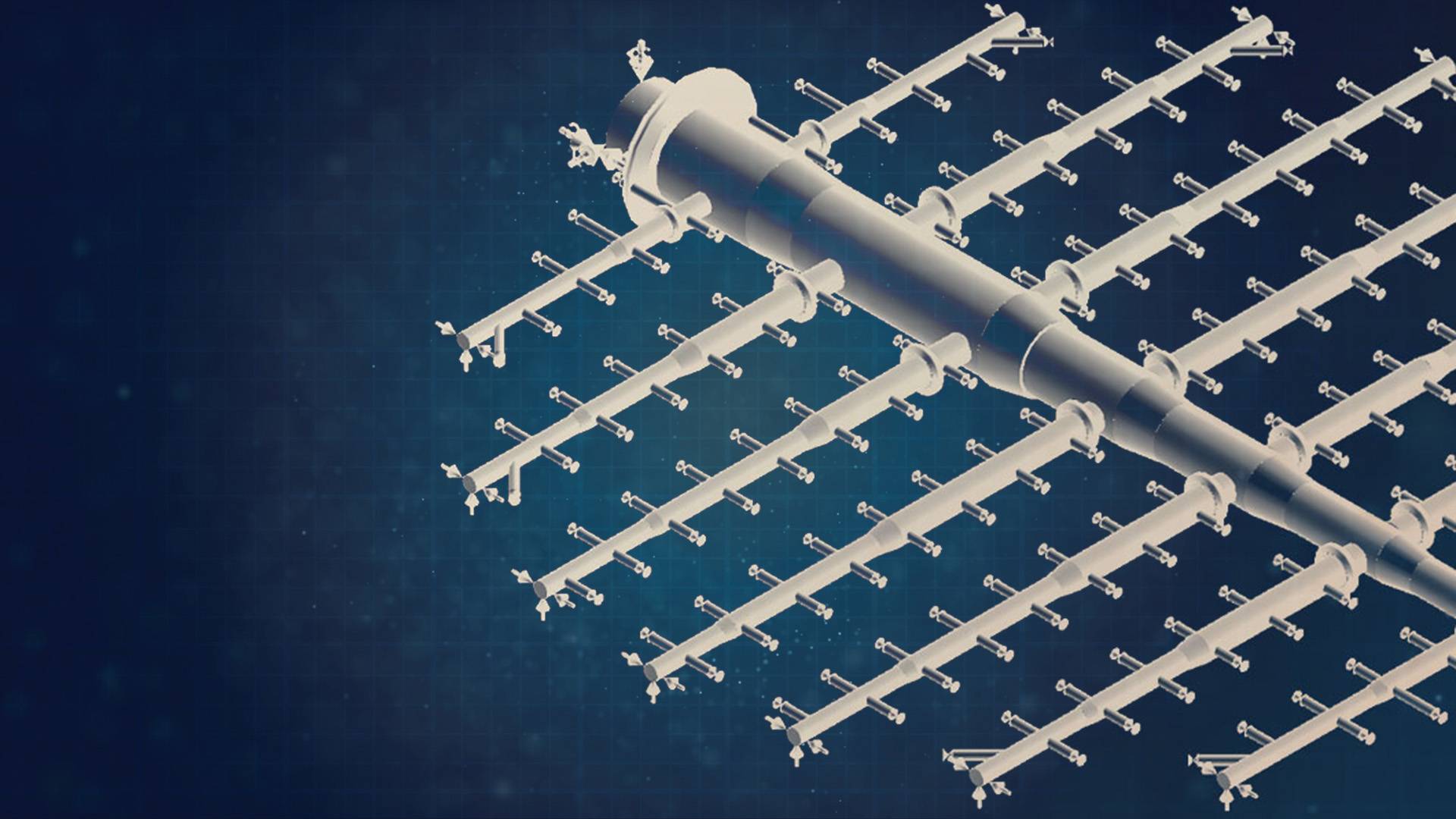

Fiberglass reinforced plastic (FRP) is an excellent material choice for a broad spectrum of corrosive fluids and, in many cases, offers best value per dollar. In addition to a corrosion resistant line, RPS provides a corrosion and abrasion resistant line, and two high temperature corrosion resistant lines. We also stock an inventory of the most commonly specified diameters in both the US and Canada.

HPPE P-150 Corrosion Resistant FRP

HPPE A-150 Corrosion and Abrasion Resistant FRP

HPPE H-150 and HPPE H-150-200 High Temperature Corrosion Resistant FRP