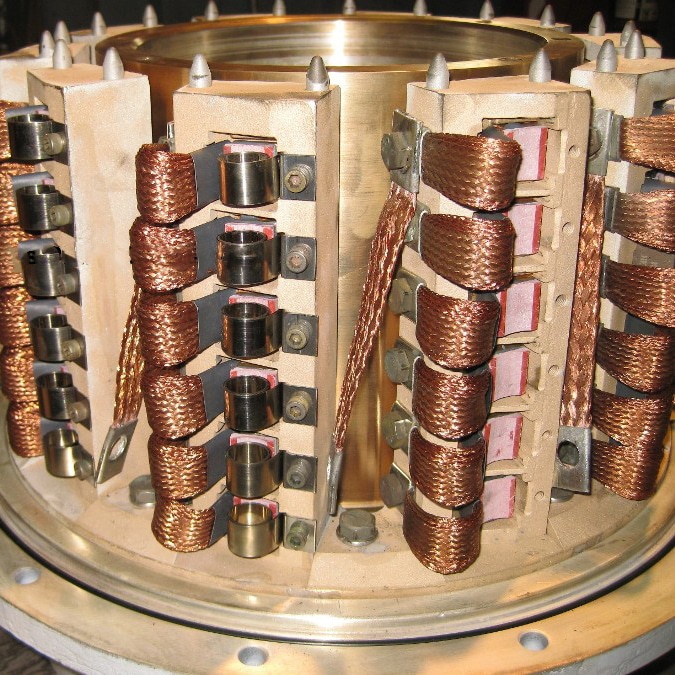

Electrogalvanizing is another highly corrosive environment due to the acid-zinc solution, and cleaning and rinsing baths, where non-metallic vessels, piping, and venting equipment are used. Most of our metals industry expertise is in our Ohio facility, where several key employees have direct experience in the steel industry.

Steel Pickling and Galvanizing

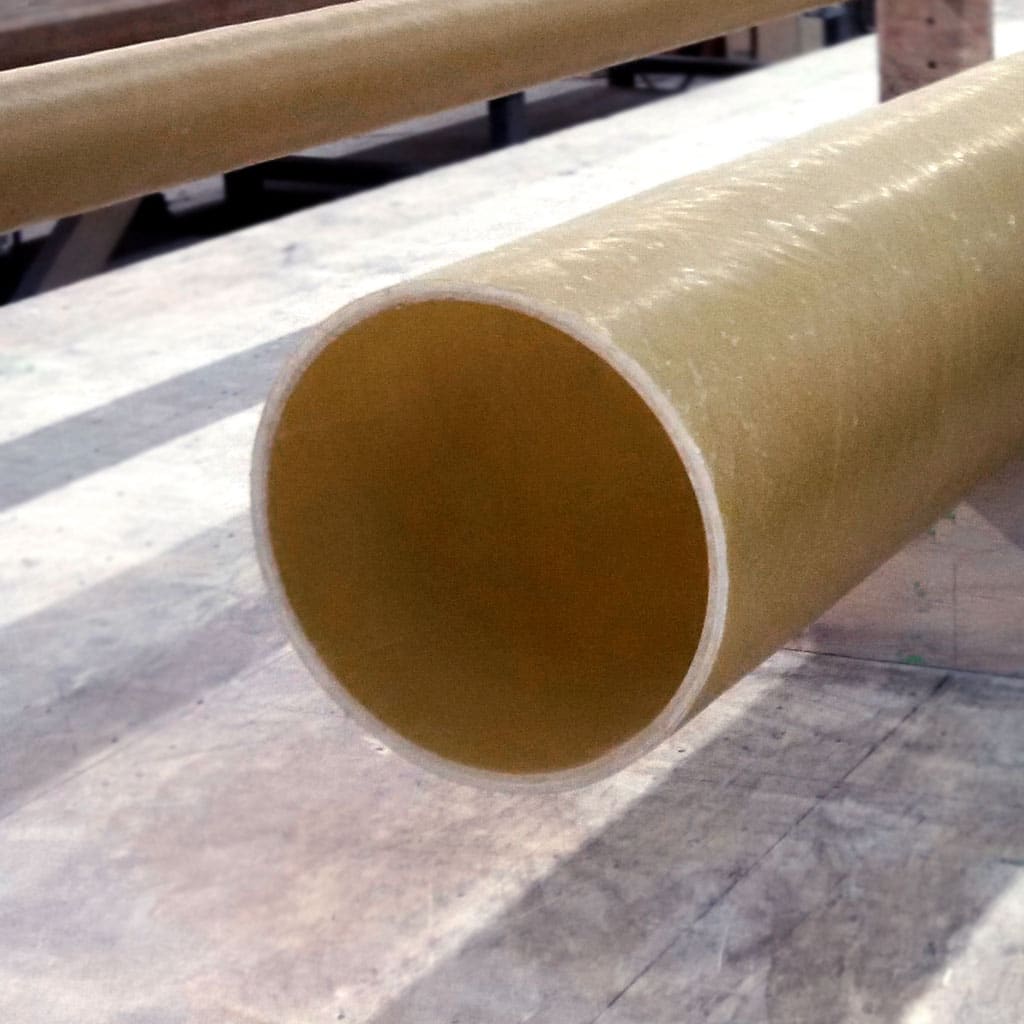

RPS Composites’ high-performance equipment excels in the corrosive atmosphere of a pickling line. This is a highly acidic environment that requires non-metallic vessels, piping, and venting equipment to contain acid, waste, and vapor. The hotter the process, the more likely that FRP will out-perform thermoplastics alone.

Top 3 Solutions Generally Used In This Industry

Case Study

Acid Wash Exhaust Stack

In the steel industry, a pickling line helps to remove dross and impurities from the end product. The steel wire or plate is dipped into or passes through a bath of hydrochloric acid and comes out smooth and clean, but it’s a hot, wet and very corrosive environment.

View project detailsThe RPS Chemical Resistance Guide

We’ve developed a number of piping systems, which have been designed to provide outstanding resistance to a wide range of chemical environments. Download our Guide to explore the RPS family of HPPE (High Performance Pre-Engineered) piping systems.

Reach out for more information about the wide variety of products and operational expertise RPS offers our customers.