We can help design and manufacture corrosion resistant tanks & vessels, piping systems, and specialty composite equipment for your project.

When performance counts, experience matters.

We deliver FRP solutions with unmatched reliability to customers all over the world.

Where reliability meets industry excellence

RPS crafts high-performance, corrosion-resistant assets that ensures operational excellence and safety. In handling corrosive materials, there’s no room for compromise. When failure isn’t an option, the world’s industrial leaders turn to us for certainty in performance and innovation.

Get to know usWe are committed to helping our customers succeed.

Our experience and unmatched skill help us handle tough situations easily, delivering results that go above and beyond.

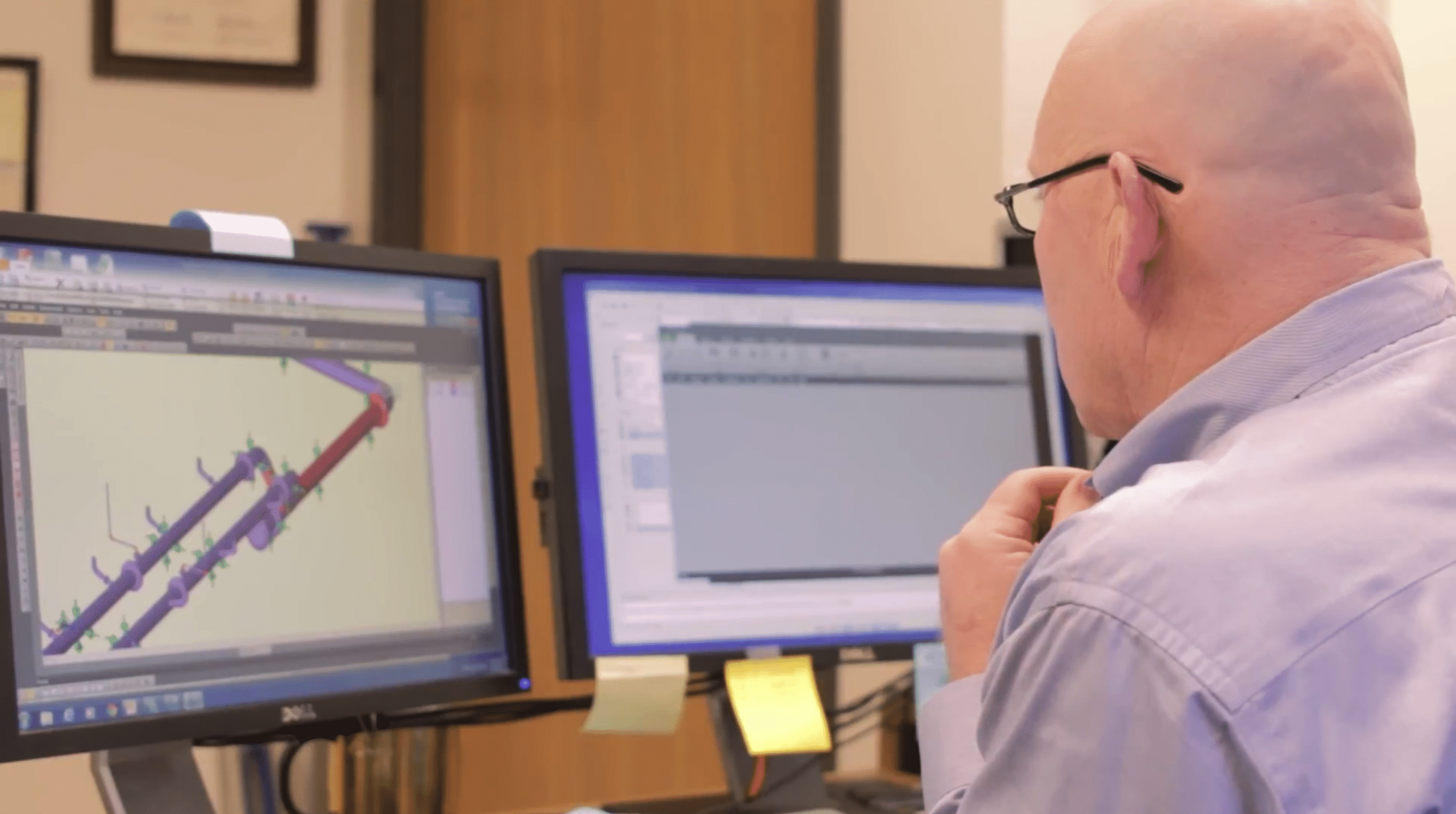

World Class Engineering Services

When you choose RPS, you gain access to industry-leading professionals dedicated to ensuring the success and longevity of your endeavors.

From project design & manufacturing to service & maintenance, we’ve got you covered.

Your strategic advisor

With decades of proven success, our experience and unmatched skill help us handle tough situations easily, delivering results for our customers that go above and beyond.

“RPS is truly a technology leader for FRP and Dual Laminate piping solutions.”

ASME Certified

RPS Composites is certified by ASME to fabricate FRP (fiberglass reinforced plastic) and dual laminate tanks and vessels to the ASME RTP-1 Standard.

View tanks and vesselsThe RPS Chemical Resistance Guide

We’ve developed a number of piping systems, which have been designed to provide outstanding resistance to a wide range of chemical environments. Download our Guide to explore the RPS family of HPPE (High Performance Pre-Engineered) piping systems.

With our extensive experience and innovative approach, we tackle not only existing challenges but can also help make sure you’re ready for any possible future challenges.