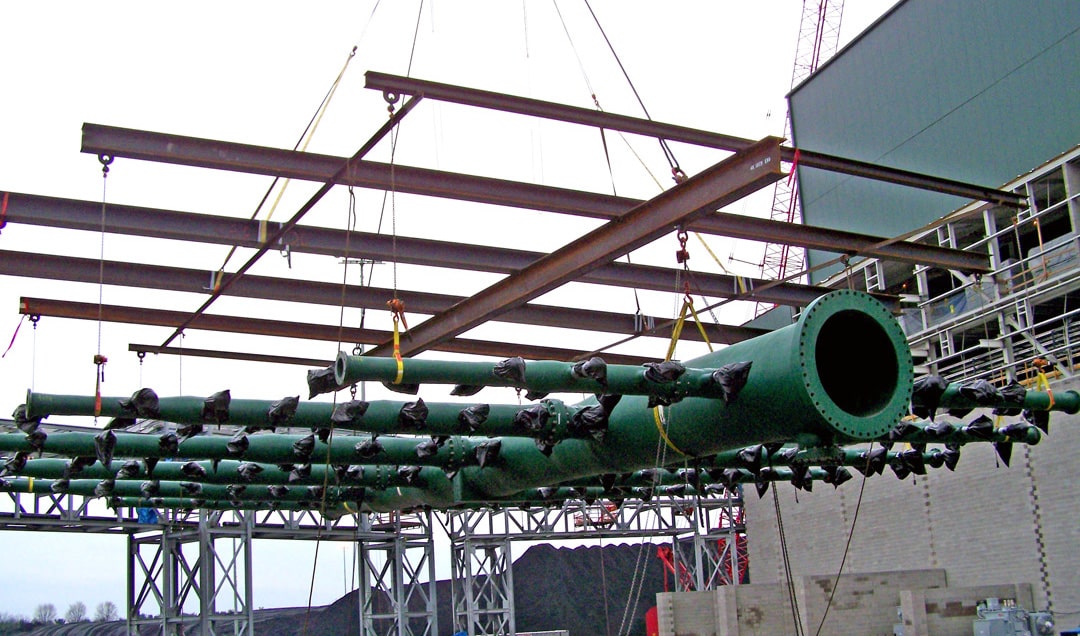

RPS will also be there to support our coal power plant customers with field service and replacement equipment for FGD, CCR, ELG, and CCUS projects. This includes recycle pipes, internal absorber spray pipes, mist eliminator wash pipes, limestone and gypsum slurry process pipes, seawater process pipes, CCR piping, cooling water piping, duct, wastewater piping, and complete internals for jet bubbling reactors. In these applications, our abrasion and corrosion-resistant composites have proven to be cost effective while providing superior performance to rubber lined carbon steel and high nickel alloy materials.

Power Generation

With much of the world focused on energy transition, RPS stands ready to respond with custom-fabricated corrosion resistant, non-conductive composites. Electrolysis, geothermal energy, nuclear energy, critical mineral processing, EV battery recycling, and energy storage are just a few applications where FRP and dual laminate provide the strength, chemical resistance, and low cost of ownership that industrial companies are looking for.

Top 3 generally used solutions in this industry

“I just wanted to take the time to thank you and your crew on a job well done. I know it was a challenge to mobilize on such short notice and to pull everything together. The guys did a great job on the repairs in good time.”

Case Study

Replacement of Failed Steel Pipe

After several years of significant maintenance cost associated with repairing and relining a specific steel pipe, plant operators and engineers evaluated their options for replacement. Based on proven performance and cost savings they chose the RPS “A” series pipe system.

View project detailsJBR Internals

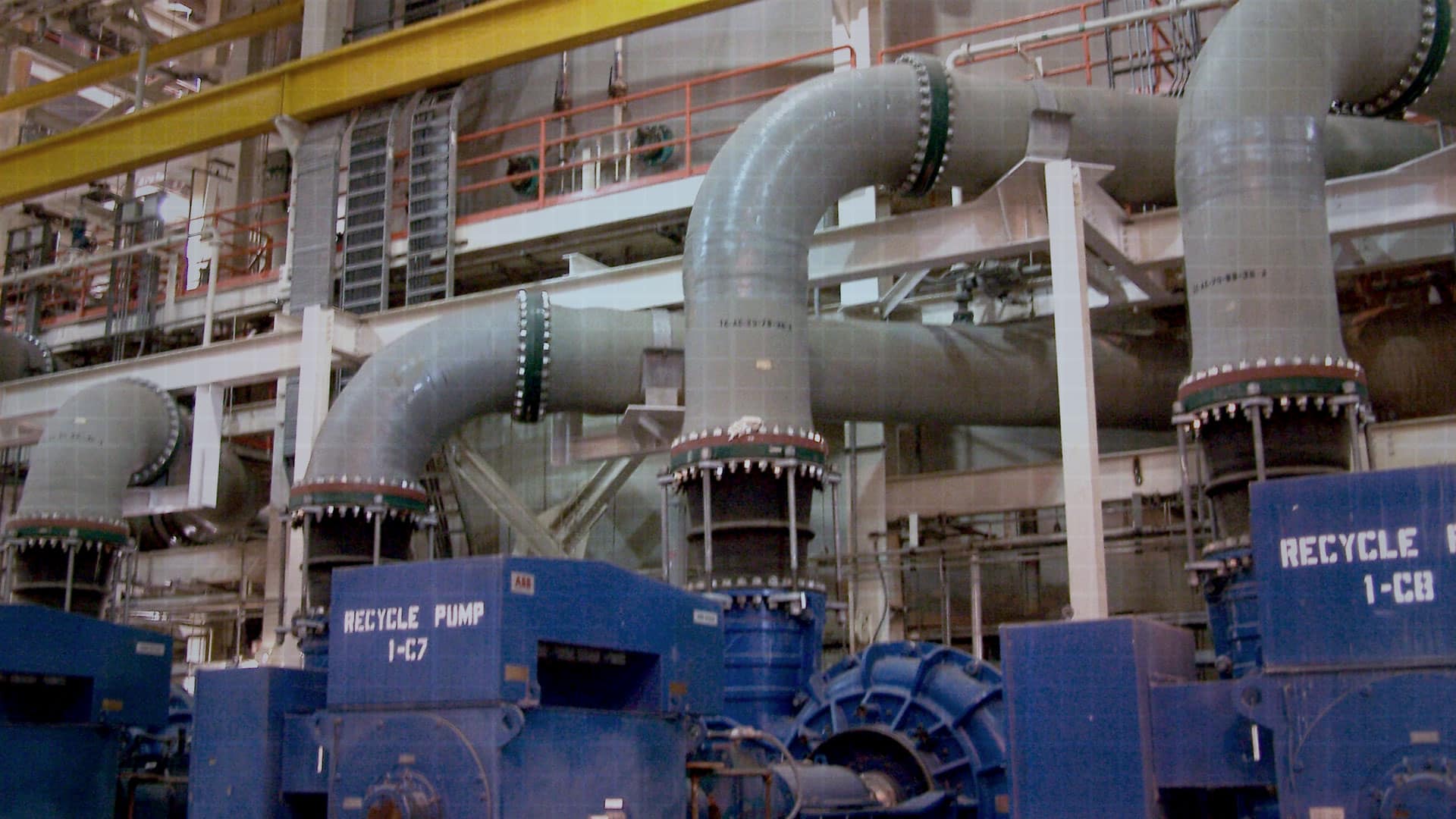

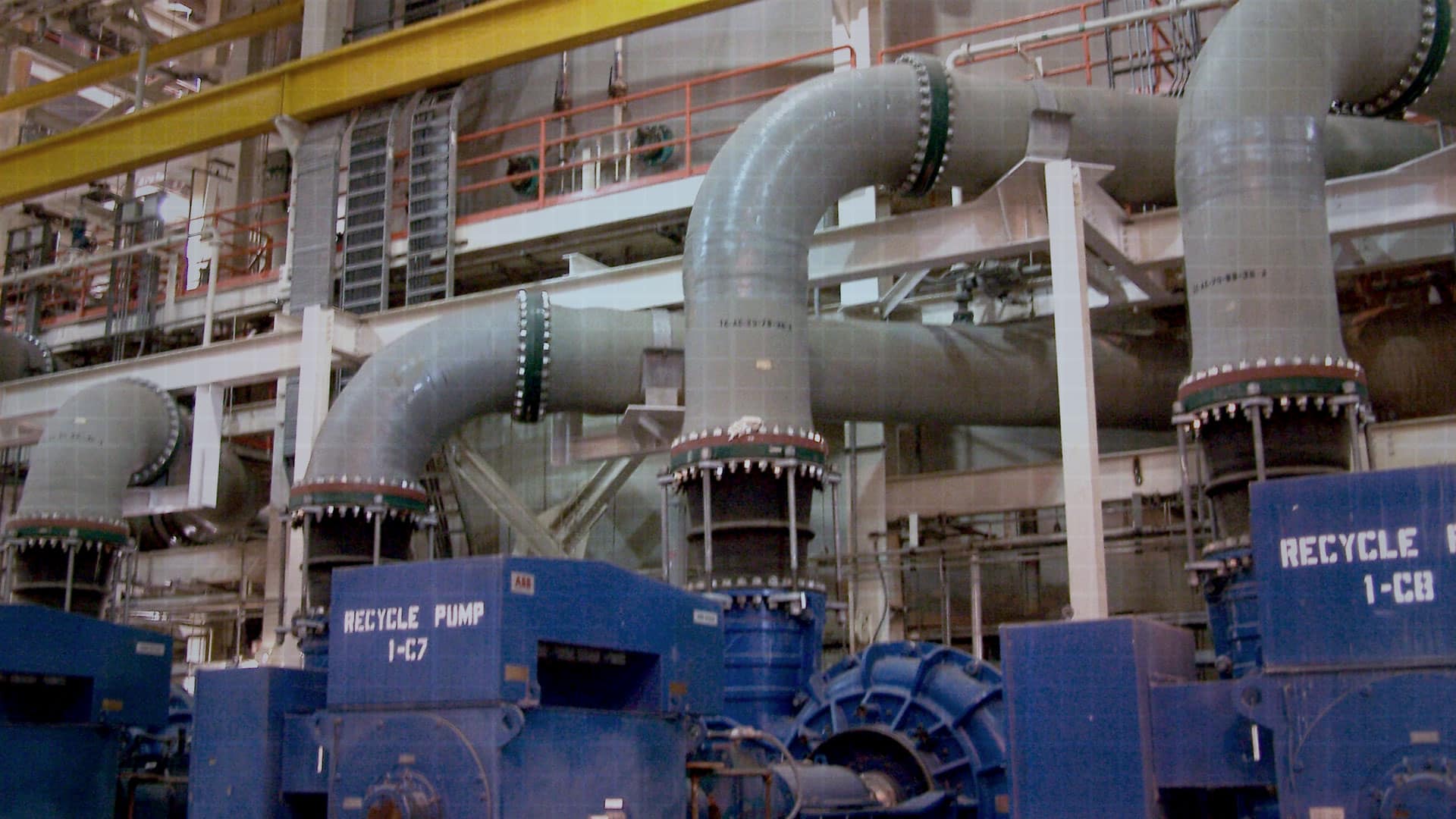

A jet bubbling reactor is one of several methods used by coal-fired power plants to reduce SO2 emissions. The environment inside the reactor is highly corrosive. Over time, FRP has proven to be, un-questionably, the material of choice for JBR internals.

RPS Composites has partnered with design experts at some of America’s largest utility companies to manufacture FRP equipment that helps extend the life of their FGD assets. RPS is the industry leader in the design and manufacture of FRP decks, down comers and gas riser tubes, FRP beams and columns, and FRP deck wash pipe and pipe supports. RPS vacuum-infused FRP alignment grids are un-matched in cost and quality, and have become the product of choice at many large utilities. The figure below illustrates a typical JBR.

RPS Composites’ piping and equipment have a proven track record in over 200 FGD plant installations dating back to 1970. RPS not only fabricates JBR internals, but our Field Service division has more experience in the installation and maintenance of JBR internals than anyone in North America.

Whether you’re focused on service, retrofits, or replacement, choose a company that has been supporting the FGD industry from the beginning. Choose RPS.

The RPS Chemical Resistance Guide

We’ve developed a number of piping systems, which have been designed to provide outstanding resistance to a wide range of chemical environments. Download our Guide to explore the RPS family of HPPE (High Performance Pre-Engineered) piping systems.

Reach out for more information about the wide variety of products and operational expertise RPS offers our power generation customers.