-

Services provided: dual laminate field joining, project management, QA of the field joints, site supervision

-

Industry: Industrial Contracting

-

Location: USA

Home / Case Studies / Industrial Contracting / USA

6,000 U-PVC FRP Field Welds

Most General Contractors (GCs) have very skilled teams with considerable knowledge and experience, and some have workers with specific skills in high demand. But for those jobs that demand distinct craftwork capability and capacity, a GC will sub-contract the work, and that’s exactly why we got a call from a prominent GC in Louisiana last year.

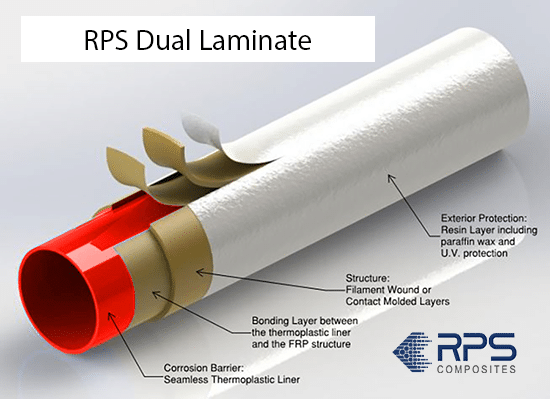

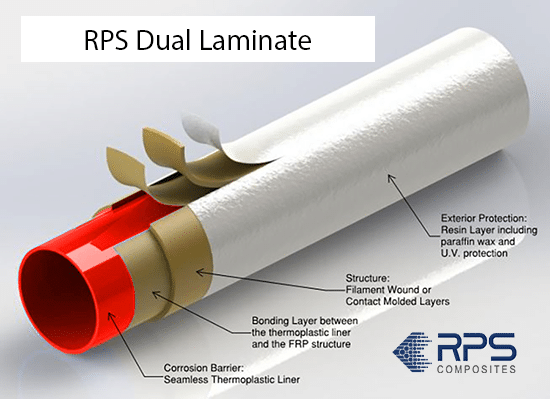

A very large chemical processor was building a new plant and because of the corrosive processes on site, thousands of feet of dual laminate piping were being installed. Dual Laminate pipe systems incorporate a thermoplastic liner, in this case U-PVC, in an FRP structure combining the enhanced corrosion resistance of thermoplastics with the higher strength and load carrying capabilities of FRP. To join the pipe and fittings in the field our teams use butt joints, accomplished by welding the liner sections and then laminating the FRP layers as per ASTM D6041. The liner weld was accomplished in this case with handheld hot gas welding, and welds were spark tested to ensure quality prior to the FRP overwrap.

This was a significant, sustained project that spanned 12 months from Spring 2020 to Spring 2021 and our crew members would perform close to 6,000 welds on ½-inch to 50-inch dia. pipe and fittings. With its complexity and coordination demands, we provided an on-site Project Manager, two Quality Control Technicians, and a Site Superintendent. Our crew size flexed according to schedule, with an average of 12 members, and expanded to 27 team members at the high point.

Plastic lined pipe is still a novel material on many job sites, and requires special handling, storage, fabrication, and troubleshooting expertise. Our crews are well-trained, and safety conscious, qualified for thermoplastic welding and FRP bonding. Both the GC and the asset owner felt we did an outstanding job on this project.

Return to all case studiesThe RPS Chemical Resistance Guide

We’ve developed a number of piping systems, which have been designed to provide outstanding resistance to a wide range of chemical environments. Download our Guide to explore the RPS family of HPPE (High Performance Pre-Engineered) piping systems.

Reach out for more information about the wide variety of products and operational expertise RPS offers our customers.