A carpenter is only as good as his or her tools, so when we heard that Ashland, our preferred resin supplier, was launching a new resin, they certainly had our attention. According to their website, Derakane Signia holds many promises, including low styrene emission, improved secondary bonding, and verifiable resin identification.

RPS is committed to delivering superior product quality across all Derakane epoxy vinyl ester resin types by developing custom resin formulations that complement our processes and fabricating environment.

Resin substitution requires careful due diligence and various trials and tests must be conducted to determine if a newly released resin is fit for use in a production environment. Cured mechanical and chemical properties of resins in a product family may be the same (e.g: Derakane Signia, Derakane 411 C-45 and Derakane 411-350) but there can often be key differences between the resin systems that affect production turnaround times (high reactivity, viscosity, wet out, etc.).

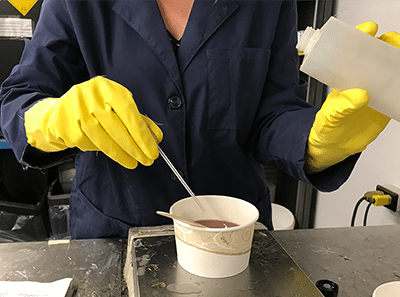

RPS followed a rigorous qualification program to test the new Signia 411 in Mahone Bay, NS in June 2018. We performed lab tests (cup gel tests and secondary bond (peel) tests) to establish target resin formula criteria such as gel time and peak exotherm levels to help develop initial resin formulations. Using the results of these tests we fabricated filament wound pipe, elbows and flanges to gain key production feedback and identify critical factors like workability and processability.

The results of our testing showed that Derakane Signia has improved secondary bonding characteristics and superior material wet out. We will be working with Ashland over the coming weeks to iterate our formulations and are enthusiastic about expanding our tool kit.

If you’re also an advocate of Ashland and their premium resins, be sure to list their materials by name in your specs.