In our last article, we looked at how an FRP pipe stress analysis is carried out. One of the outputs of such an analysis is the loads on the restraints. It is these loads that serve as the inputs to the pipe support design. The next step in the piping design process is to convert the analysis results into a properly functioning FRP piping support system.

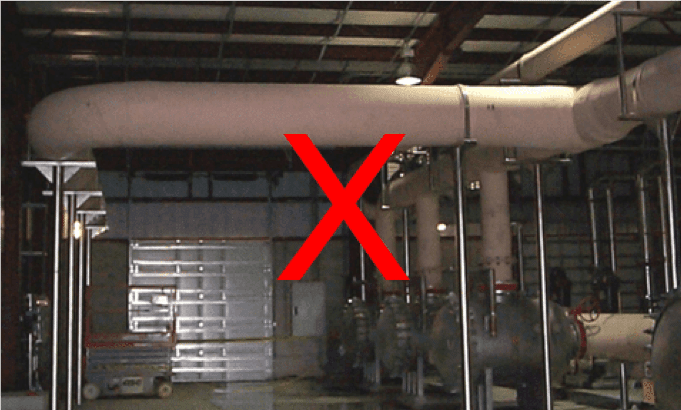

In any piping system, it is necessary that the support and support system be configured to behave as intended in the piping design. The support must be physically configured to provide the type of restraint that was assumed in the design. For example, if the particular support was intended to act as a guide, i.e. to provide lateral restraint for loads such as wind or seismic, then it must be strong enough and stiff enough in the lateral direction to provide the required restraint. The photo below indicates a situation where the guides were not properly configured. Being on tall posts like this results in the supports having very little lateral stiffness. The piping will therefore be allowed to deflect laterally to a much greater extent than would likely have been assumed in the design.